Ahmedabad, Gujarat

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Physical State | Powder |

| Turbidity | 5 ntu |

| Packaging size | 500ML, 1 LTR, 2.5 LTR, 5 LTR, 25 LTR |

| Click to view more | |

Preferred Buyer From

| Location | India, Afghanistan, Bahrain, Bangladesh, China, Hong Kong, India, Indonesia, Iran (Islamic Republic of), Iraq, Israel, Japan, Jordan, Kuwait, Malaysia, Nepal, Oman, Pakistan, Philippines, Saudi Arabia, Singapore, Korea, Republic of, Sri Lanka, Syrian Arab Republic, Taiwan, Thailand, Turkey, United Arab Emirates, Viet Nam, Yemen, France, Germany, Greece, Italy, Netherlands, Poland, Romania, Russian Federation, Spain, Ukraine, United Kingdom |

Product Details

Description for Glycolic Acid : Glycolic Acid (The Eco-friendly and most Versatile Acid)

Product Overview :

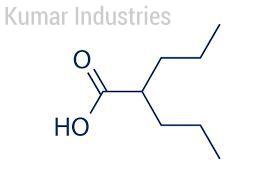

- Glycolic acid (Hydroxy acetic Acid) is the first member of the series of alpha-hydroxy carboxylic acids. Although it occurs naturally as a trace component in sugarcane, beets, grapes and fruits, the vast majority of commercially available material is manufactured synthetically. The formula for glycolic acid is HOCH 2 COOH and its molecular weight is 76.05. It is listed as "acetic acid, hydroxy-" in the Chemical Abstracts. Its CAS Registry Number is 79-14-1.HOCH 2 COOH. Glycolic Acid is very soluble in water, methanol, ethanol, acetone, acetic acid and ethyl acetate. It is slightly soluble in hydrocarbon and ether solvents.

- Kumar Industries supplies Glycolic Acid as a 70% technical aqueous solution; as a 70% high-purity aqueous solution (Glyshudh 70) and as high purity crystals (Glyshudh 99). Glycolic acid customers can be assured of a reliable supply of quality material.

Product Attributes

Glycolic Acid has a unique combination of properties that makes it valuable in a wide variety of end-uses, especially when de-scaling is needed :

- Low corrosiveness

- Negligible Volatile Organic Compounds (VOC)

- Non-flammable

- Low odour

- Low toxicity

- Readily biodegradable

- High water solubility

- Easy handling liquid form

- Solubilizes hard water salts.

- Glycolic acid's ability to complex metal salts gives it many uses in household and industrial cleaning applications. Its dual chemical functionality (its acid and alcohol groups), makes it a particularly useful organic chemical intermediate. Glycolic acid has applications in many industries, including personal care, textile, transportation, petroleum, food processing and water treatment. Aqueous solutions of glycolic acid contain free acid and soluble oligomers in equilibrium.

Market Applications :

- Household and Institutional Cleaners

- Glycolic acid has many properties that make it an ideal component of household and institutional cleaner systems. Its dissolution capabilities for hard water salts (magnesium, calcium), soap scum and iron oxide give it excellent cleaning characteristics. The dissolved salts are easily rinsed away. In addition, it has very low odor, is light in color, and in nonflammable. It is also readily biodegradable, and has negligible VOC (<0.1 mm pressure at 20 ° C [68 ° F]).

- Glycolic acid is compatible with most other acids (though care should be exercised with strong oxidizing agents) and with other components used in formulations such as surfactants and glycol ether solvents, as well as many fragrances and dyes. Testing has shown that the inclusion of glycolic in acid hard-surface cleaners generally results in improved or superior cleaning performance.

Industrial Cleaners :

- Stainless Steel Boiler and Process Cleaning Equipment.

- Calcium carbonate and iron oxide mill scale can be removed by glycolic acid alone or by synergistic mixtures of glycolic and other acids. Where corrosion is an issue, such as in high pressure stainless steel boiler systems, a mixture of 2%glycolic acid and 1% formic acid has been found to be very effective. The low chloride content of glycolic acid minimizes the potential for chloride stress corrosion damage.

- The glycolic/formic acid mixture offers the following advantages :

- Effective removal of scale deposits

- Freedom from organic iron precipitation

- Low corrosion due to negligble chloride content

- Biodegradable wastes

Dairy Cleaning : The unique combinations of glycolic acid's properties make it an excellent acid cleaner for removing milk stone, casein and other deposits from dairy processing equipment. Glycolic acid dissolves and complexes hard water scale more effectively than phosphoric acid. Waste materials and any un-reacted acid are easily washed away with a final rinse of potable water.

Food Processing Equipment Cleaning : The use of glycolic acid in the cleaning of meat, poultry and egg products processing equipment, providing these food contact surfaces are rinsed with potable water after cleaning.

Transportation Cleaning : Because of its low toxicity, glycolic acid is the ideal replacement of more toxic acids such as oxalic, which is commonly used in the cleaning of stainless steel and aluminum, rail cars, as well as truck bodies, "Mag" wheels. Glycolic acid's low corrosiveness, good salt solubility and high rinsability, low odor and ready biodegradability contribute to its attractiveness in these applications.

Masonry : Glycolic acid can be used alone or in mixtures with other acids, particularly phosphoric acid, to produce an effective cleaner for bricks and concrete. Some clay used in making white bricks contain traces of metals that cause staining as they migrate to the surface during kiln firing. Glycolic acid's complexing ability affords effective removal of these metals.

Paper Maker Felt Cleaning : Because of its ability to complex aluminum salts, as well as other hard water salts, glycolic acid can be valuable in conditioning papermaker felts. It is non-damaging to the nylon components of these paper felts.

Water Treatments :

- Cooling Tower and Heat Exchanger Cleaning

- Glycolic acid will effectively remove hard water scale from all types of heat-exchanger equipment. Due to its low corrosiveness, odor, and negligible volatility, it should be considered for pH adjustment of cooling water to prevent scale accumulation.

Water Well Cleaning : Glycolic acid complexes and removes accumulated iron and carbonate deposits in water wells. Glycolic acid removes the scale which suppresses the flow of water. In addition, anecdotal and technical literature reports indicate that such treatment is particularly effective where flow is suppressed due to the presence of slime and iron metabolizing bacteria. Glycolic acid is easily handled because of its liquid form, low corrosiveness and lack of fumes. It also has no solubilization problems. Waste disposal from well cleaning is facilitated by glycolic acid's ready biodegradability and its ability to prevent salt precipitation even as the pH is increased. Glycolic acid does not replace the need for phosphate treatment used to aid clay removal.

Metal Processing :

- Metal Pickling

- Glycolic acid can be used to replace volatile acids in special pickling operations. The negligible volatility prevents losses due to elevated temperatures and reduces ventilation requirements.

Copper Brightening : Glycolic acid can be used to give luster to copper and copper alloys, following normal pickling operations. This luster has been found to be retained much longer than when strong oxidizing acids are used. Polishes for copper utensils, like pots and pans, can also be formulated with glycolic acid as the primary active ingredient.

Electroplating/Electroless Nickel Plating : Glycolic acid is used in numerous electroplating applications. The sodium and potassium salts of the acid are excellent substitutes for Rochelle salts used in bath additives. Because glycolic acid forms complexes with virtually all multivalent metals, its salts can be used in aluminum, chrome, lead, cobalt, tin, and nickel electroplating baths. Glycolic acid can also be used to clean and condition substrates prior to electroless plating. The sodium salt of glycolic acid can be used for nickel electroless plating.

Electropolishing : Glycolic acid, usually in combination with phosphoric acid and/or sulfuric acid, may be used in the electropolishing of stainless steel. The mixture provides a bath with long life and reduced sludging characteristics.

Electronics :

- Printed Circuit Board Processing

- Glycolic acid has several uses in the electronics industry. Its characteristics make it an effective and environmentally safe means of conditioning and de-oxidising circuit boards. It is also used as a solder flux component. Its water soluble metal complexes give excellent rinsibility.

Leather Industry : Glycolic acid has several applications in the leather industry. It can be used to replace formic acid in leather dyeing and in combination with stronger mineral acids to improve deliming. Glycolic acid has been observed to improve the grain of leathers by reducing fine lines and wrinkles in the hides. It can be used to adjust the pH in tanning and dye baths. The sodium salt of glycolic acid can be used as a masking agent. Tris-(hydroxyacetato)-chromate, a glycolic acid chromium compound, has been used to improve chrome tanning.

Textile Dyeing and Finishing : Due to its negligible volatility and low odor glycolic acid is a good replacement for other organic acids, such as acetic acid, in textile dyeing and finishing applications. The complexing ability of glycolic acid is of benefit in managing metal ions present in the bath water, rinses, etc. It is used for dyeing chrome colors, but is not recommended for colors that are easily reduced. It is a good substitute for cream-of-tartar in mordanting wool with chrome, because it combines good exhaustion with good reduction. Glycolic acid can also be used as a solvent in liquid cationic dye products and to dissolve solid cationic dyes.

Laundry Sour : As a laundry sour, glycolic acid's liquid form and high solubility in water make it ideal for automatic liquid-dispensing laundry equipment. Because it does not buffer, the addition of glycolic acid can be directly controlled by pH. Its excellent rinsability minimizes the amount of acid retained by the fabrics, thereby reducing the mechanical and chemical damage that can occur with silicafluoride salts. Because glycolic acid is readily biodegradable, waste disposal is easy.

Oil and Gas Well Applications : Acid Well Stimulation - Acidizing Glycolic Acid alone or in combination with other acids like hydrochloric or hydrofluoric is injected into the formation, dissolving a portion of rock and creating a large pore structure in the formation, thus increasing the flow of oil. Glycolic acid is used in conjunction with hydrochloric or sulfamic acids to prevent iron precipitation in cleaning operations or in water flooding.

Adhesives :

- The ability of glycolic acid to react with casein to form cationic casein glycolates has been used to manufacture adhesives. These derivatives can also be used in textile sizing applications.

- Lubricating Oil Additives - Glycolic acid is used to provide enhanced dispersion and detergency in automotive lubricating oil.

- Cement Strengthening - Glycolic acid, used in concentrations of 0.01% to 0.1% w/w. has been found to increase the compressive strength of cement, as well as act as a water retardant.

Glyshudh™ - High Pure Glycolic Acid :

- Some applications require the use of high-purity glycolic acid. Glyshudh™- 70% Solution and Glyshudh™- 99% Crystals have undergone additional purification steps to reduce color and remove organic impurities. Glyshudh - 99% is also useful where minimal water is required.

- Personal Care Applications - Glycolic acid is the premier alpha hydroxycarboxylic acid (AHA). AHAs have found application predominantly in skin care products; however, many companies are now using them in other personal care applications including shower gels, soaps, shampoos and conditioners.

Chemical and Physical Stability :

- Glycolic acid 70% technical solution and Glyshudh70% solution are chemically stable when stored at normal temperatures. The solution products are physically stable if they are stored at temperatures above 10 o C (50 o F). At colder temperatures, glycolic acid crystals can form. The crystals can be put back into solution by warming the container with stirring. This does not affect chemical quality. Kumar personnel can provide detailed procedures for reconstituting precipitated glycolic acid.

- The Glyshudh 99% crystalline grade of glycolic acid is chemically stable to 50 o C (122 o F).Above this temperature, polymerization begins to occur. Kumar guarantees the specification chemical quality of its glycolic acid products for two years, provided the container has not been opened. Kumar will help customers determine if the quality of their glycolic acid is still viable.

Precautions in Use : As a moderately strong acid, glycolic acid will react in a typical fashion with carbonates to release carbon dioxide gas; with cyanide salts to release hydrogen cyanide; with sulfide salts to release hydrogen sulfide and with active chlorine compounds (like chlorine bleach) to release chlorine. It will also react with active metals (like sodium) to release hydrogen. Glycolic acid has typical reactions with strong oxidizing agents like nitric acid, to form intermediate compounds like glyoxylic acid, oxalic acid and (ultimately) carbon dioxide.

Looking for "70% Glycolic Acid" ?

Explore More Products